DINGSHANG Stainless offers stainless steel coil tubing in long lengths, tube sizes are 1/4, 3/8, 1/2, and 3/4 inch in outside diameter and 0.035 to 0.083 inch in wall thickness, we are capable of producing welded stainless tubing in coils, the welded tube can exceed 2000 meters in one continuous coil without any longitudinal or orbital welds. Coiled tubes are no joints linking separate sections to each other, compared to straight tubing, coiled tubing reduces installation time and costs as well as eliminates potential leak points.

Stainless steel coil tubing material includes stainless steels, duplex steels as well as nickel alloys, and is finished in bright annealing surface condition according to ASTM A249 / A269 standard specifications. We can also offer PVC-coated coils to order.

Stainless Steel Coil Tubing is designed for liquid or air supply lines, tubing coil is ideal for use with low or high-pressure solutions such as oils, chemicals, gases and solvents, it can also be used for low-pressure chemical transfer, gas lines, airlines and more. tube coiling can be used with a wide variety of compression and fittings depending on the application.

1/4 | 3/8 | 1/2 | 3/4 Stainless Steel Coil Tubing

| Standard | ASTM A249, ASTM A269 |

| Material | 304/304l, 316/316L, 321 |

| Tube Type | Welded Tube |

| Finishes | Bright Annealed |

| Outside Diameter | 3.18 Up To 50.8 mm |

| Thickness | 0.3 Up To 2 mm |

| Coil Diameter | Max 1500 mm |

| Coil Shapes | helix, box, double, round, and irregularly shaped coils |

| Application | heating, cooling and mechanical applications, heat exchanger coils, condenser coils, oxygen-warming coils, oil-cooling coils and beverage coils |

304/304L Stainless Steel Coil Tubing

304 Stainless Steel Is the most versatile and widely used of stainless steel grades, due to its combination of corrosion resistance, formability, and ductility. It is ideal for food and beverage, pharmaceutical, chemical, and petrochemical processing applications.

304/L (UNS S30400/UNS S30403) Chemical Composition % (Max.)

| UNS | C Carbon | Mn Manganese | P Phosphorous | S Sulfur | Si Silicon | Cr Chromium | N iNickel |

| S30400 | 0.080 max | 2.00 max | 0.045 max | 0.030 max | 1.00 max | 18.0–20.0 | 8.0–11.0 |

| S30403 | 0.030 max | 2.00 max | 0.045 max | 0.030 max | 1.00 max | 18.0–20.0 | 8.0–12.0 |

316/316L Stainless Steel Coil Tubing

316 Stainless Steel provides the best resistance to pitting and corrosion of any of the austenitic (300 series) stainless steels and is best for wine applications. It is extremely ductile, with excellent strength at elevated temperatures. It is ideal for hydraulic and instrumentation tubing in chemical, textile, and pulp and paper industries, and in marine environments.

316/L (UNS S31600/UNS S31603) Chemical Composition % (Max.)

| UNS | C Carbon | Mn Manganese | P Phosphorous | S Sulfur | Si Silicon | Cr Chromium | Ni Nickel | Mo Molybdenum |

| S31600 | 0.080 max | 2.00 max | 0.045 max | 0.030 max | 1.00 max | 16.0–18.0 | 10.0–14.0 | 2.00–3.00 |

| S31603 | 0.030 max | 2.00 max | 0.045 max | 0.030 max | 1.00 max | 16.0–18.0 | 10.0–18.0 | 2.00–3.00 |

Nickel Alloy 825, 625 Coil Tubing

| Grade | UNS | C(Max.) | Cr | Ni | Mo | Others |

| Alloy 825 | N08825 | 0.03 | 20 | 38.5 | 2.6 | Cu=1.7, Ti=0.7 |

| Alloy 625 | N6625 | 0.1 | 21.5 | >=58 | 9 | Nb=3.5 |

Stainless Steel Coil Tubing Dimensions

The diameter of the tubes can be as little as an inch or less up to several inches or more, depending on the requirements of the application; and the thickness of the pipe is also highly customizable. There are various configurations achievable too, from single and dual helices to nested coils and continuous spools.

The standard outside diameter and wall thickness, maximum length reaches 2500 meters.

| Coil Tubing | Outside Diameter | Wall Thickness |

| Welded 304/L | 1/8“, 3/16“, 1/4“, 5/16, 3/8“, 1/2“, 5/8“, 7/8“, 3/4“, 1”, 1”-1/2 | 0.02″, 0.035″, 0.049″, 0.065″, 0.083″ |

| Welded 316/L | 1/8“, 3/16“, 1/4“, 5/16, 3/8“, 1/2“, 5/8“, 7/8“, 3/4“, 1”, 1”-1/2 | 0.02″, 0.035″, 0.049″, 0.065″, 0.083″ |

Metric coils are available in popular sizes:

8mm x 1.5mm, 10mm x 1mm, 10mm x 1.5mm, 12mm x 1mm, 12mm x 1.5mm

Stainless Steel Coil Tubing Quality

- Precision coiling

- Standard tolerance: ASTM A269

- Surface/cleaning visual control

- OD tolerance: +/- 0,10 mm (before rolling up)

- OD tolerance: +/- 0,15 mm (before rolling up)

- Wall Thickness: +/- 10%

- 100% Eddy Current

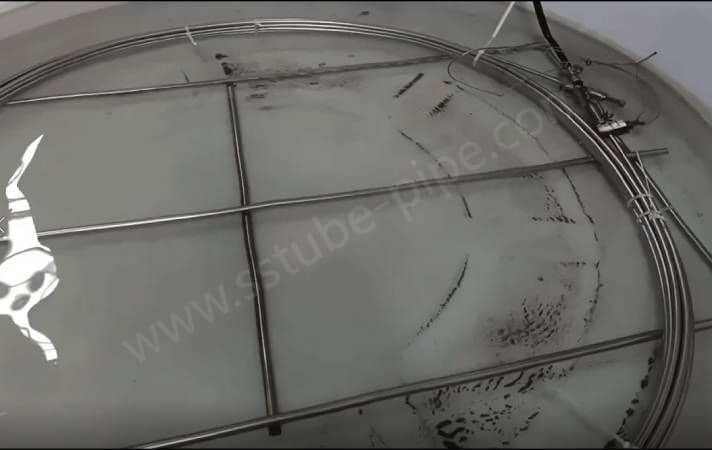

- Leak – Air Under Water Test

- Pressure control underwater

- Control with EN 10204/3.1 certificate

Advantages Of Coil Tubing

The traditional method of welding long stick tubing end to end or with fittings is a very labor-intensive procedure, this welding process is very slow and costly, using coil tubing not only takes a fraction of the time, reducing labor costs, but it also provides for a much safer and maintenance free installation.

Stainless Steel Tubing Coil for Chiller

Tube coiling is a specialized process in which the length of a tube or pipe is formed into a helical spiral shape that resembles a spring. The process is used to create bespoke tubes for a wide number of applications and environments, from the automotive industry to refrigeration and air conditioning and the distillation of alcoholic beverages.

- 304 stainless steel and type 316 stainless steel

- 18ft, 25ft, 50ft, and 100ft lengths

- With standard compression fitting or clamp tubing directly to it

- Use for cooling beer, malt, Brewing and Distilling

- This chiller rapidly chills your wort in as fast as 15 minutes

- Durable, more corrosion resistant, and considerably cheaper than similar copper chiller coils

Stainless Steel Coil Tubing For Heat Exchanger

Coil tubing is used for a wide range of applications, applied for cooling and heating transferring energy in corrosive and non-normal temperature environments, like food and beverage, oil and gas, medicine industry.

- Evaporator Coil Tubing

- Solar Heater Coil Tubing

- Bear Cooling Coil Tubing

- Condenser, Boiler Coil Tubing

- Cooling Tower Coil Tubing

- Steam Coil Tubing

Control Line Coiled Tube

Coiled tubing (CT) refers to a continuous length of small-diameter steel pipe and related surface equipment as well as associated drilling, completion and workover, or remediation, techniques. Coiled tubing is usually packed on a coil wound on a wooden drum or spool, also specific metal reels, Encapsulated and PVC coated are available.

Coiled tubing is available in diameters of 0.75 to 4.5 in.—2 in. is the most common size. It may range in length from 2,000 to more than 30,000 ft [600 to 9,000 m]. The tubing is coiled in a single continuous length, thus precluding any need for making or breaking connections between joints. This permits continuous circulation while running in or out of the hole.

- Downhole hydraulic control lines

- Downhole chemical control lines

- Subsea control lines for hydraulic power and chemical injection line

- Flowline control

- Instrumentation tubing

- Smooth inner surface control line tubing used in fiber optic applications

To achieve the specification of coiled tubing you need for your project, you require a team of experts with the requisite experience, training and equipment. With over 15 years of experience in the industry, we have the expertise necessary to achieve the results you require.