ASME SA 249 TP 304 304L 304H 316 316L 316Ti welded stainless steel tube is manufactured complying with ASME SA 249 specification, the standard indicates the manufacturing process, material, sizes and other conditions of welded tubes for heat exchanger, boiler and condenser system.

ASME SA 249 TP 304 stainless steel contains a minimum of 10.5% chromium content by mass and has good forming and welding features, 304 also provides excellent strength, durability, and corrosion resistance. 304 welded tubing can be used in many applications, like oil and air, plant, food processing, medical and pharmaceutical field, TP304 grade is an affordable stainless steel compared to TP316 and TP316L grades.

Our Advantages

- Quality Manage system ISO9001:2015

- Wide range of sizes

- Variety of grades including Special alloys

- Custom properties and finishes

- Tighter tolerances

- In-home tests

- Unique packaging

ASME SA 249 TP 304 Stainless Steel

304 stainless steel is the most widely used of all stainless steel grades, 304 stainless steel tubing offers good corrosion resistance to many chemical corrodents, as well as industrial atmospheres. 304 stainless steel tubing offers good formability and can be readily welded by all standard methods. An extra low-carbon variation, called 304L, avoids harmful carbide precipitation due to welding. This variation offers the same corrosion resistance as 304 but slightly lower mechanical properties.

ASTM A249 TP304 Chemical Composition

| Grade | C | Si | Mn | Cr | Ni | S | P | Fe |

| TP304 | 0,08 | 1,0 | 2 | 18 – 20 | 8 – 11 | 0,03 | 0,045 | Bal. |

ASTM A249 TP304 Mechanical Properties

| Grade | Tensile Strength (Mpa) | Yield Point (Mpa) | Elongation (%) |

| TP304 | 515 | 205 | 35 |

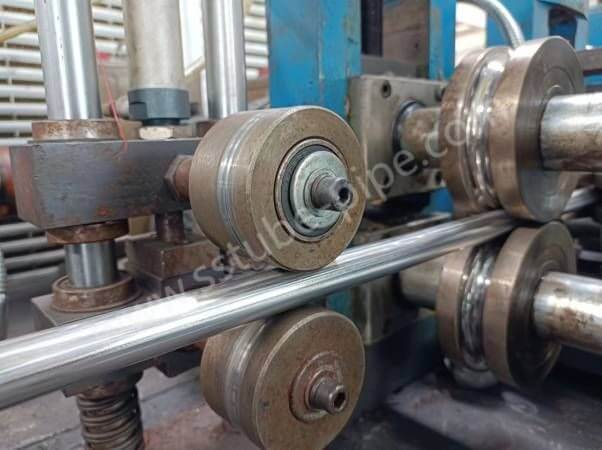

ASME SA 249 TP 304 Welded Tube Manufacturing

ASME SA 249 standard is for welded stainless steel tubes, the tubes are installed for the heat exchanger, boiler and condenser in the heating or cooling delivery system. The tube is made starting from stainless steel strip or coil, welding both edges, forming the shape, rolling inside and outside surface, that will be shape tubes, then heat treatment and the cold working process should be made conforming to this ASME SA 249.

ASME SA 249 TP304 Welded Tubes Sizes and Dimensions

ASME SA 249 stainless steel heat exchanger, boiler and condenser tubes are in a wide range of dimensions and designs, tubes can be straight or U-bent, standard sizes we offered for welded tubes are as below, custom OD and wall are available on request.

Outside diameter: ranges from 6 to 304.8 mm, standard sizes have 16, 19.05, 25.4, 31.8, 38.1, 44.45, 50.8, 76.2, 101.6 mm

Wall thickness: average thickness and minimum thickness are available, there are 0.71, 0.89, 1.0, 1.25, 1.65, 2.11, and 2.77 mm.

Tolerance of outside diameter and thickness should conform to ASME SA 249 specification and ASTM A1016/M, Wall thickness tolerances shall be +/-10 % of the nominal wall.

| Outside Diameter, in. [mm] | Permitted Variations, in. [mm] Over | Permitted Variations, in. [mm] Under |

| Under 1 [25] | 0.004 [0.1] | 0.004 [0.11] |

| 1 to 11⁄2 [25 to 40], incl | 0.006 [0.15] | 0.006 [0.15] |

| Over 11⁄2 to 2 [40 to 50], excl | 0.008 [0.2] | 0.008 [0.2] |

| 2 to 21⁄2 [50 to 65], excl | 0.010 [0.25] | 0.010 [0.25] |

| 21⁄2 to 3 [65 to 75], excl | 0.012 [0.3] | 0.012 [0.3] |

| 3 to 4 [75 to 100], incl | 0.015 [0.38] | 0.015 [0.38] |

| Over 4 to 71⁄2 [100 to 200], incl | 0.015 [0.38] | 0.025 [0.64] |

| Over 71⁄2 to 9 [200 to 225], incl | 0.015 [0.38] | 0.045 [1.14] |

Quality Control for SA 249 TP304 Welded Stainless Steel Tubes

Tube analysis should conform to TP304 stainless steel chemical composition, like nickel alloy content and others, using a direct-reading spectrometer or PMI tester.

All tubes shall be furnished in the heat-treated condition in accordance with the required solution temperature, TP304 grade solution temperature range is from 1040 ℃ to 1150 ℃, heat number should be recorded according to the same size of each lot.

The tubes shall undergo mechanical tests such as tension test, flattening test, flange test, reverse-bend test, hardness test (Rockwell hardness), and the nondestructive test is conducted for each tube, like eddy current testing and air underwater testing.

Special testing should be stated prior to production, such as intergranular corrosion test, and welding decay test.

Mill Test Certificate should be offered according to EN 10204 3.1 type.

ASME SA 249 TP 304 U Bend Welded Tube

In heat exchanger system, it often requires U bend-type stainless steel tubes, U bending tube has benefits to save cost. leg length max 12 meters, radius max 1.5 meters, bending part should be heat treated to relieve stress, after that pickling to ensure tube surface clean.

ASME SA 249 TP 304 Bright Annealing Welded Tube

Bright annealing and annealed pickling processes can eliminate the scaling to make the inside and outside surface clean, inert gas hydrogen-air in the closed furnace, then heat treatment improves tube roughness, it makes the tube brighter, when it is installed in the heater and cooler system, that will be easy as well as to clean.