We have achieved all the required certifications, assuring customers that the quality of our stainless steel tube is high quality. The management system conforms to:

Occupational Health and Safety Management System standard ISO 45001:2018

Environmental Management Systems ISO 14001:2015

Quality Management System ISO 9001:2015

Our production standards comply with the following certifications:

Pressure Equipment Directive 2014/68/EU, Annex I, Section 4.3

AD2000 Merkblatt W0

We firmly believe in the value of tube certification, as it helps to drive up quality standards, ensure health and safety, and reassure customers about the level of service can provide. Certifications also relate directly to our quality systems, with the PED 2014/68/EU confirming the quality of our pressure testing and production equipment.

ISO 9001:2015 also confirms that processes and products comply with recognized global standards, and that the products we manufacture are of a sufficient quality to be certified by the International Organization for Standardization.

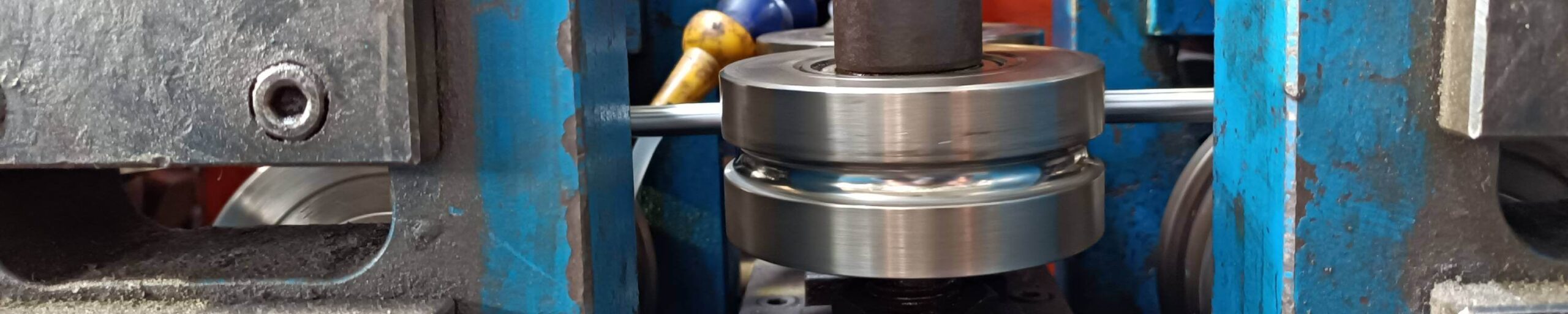

Testing and Inspection

Raw Material InspectionIn

spection of the strip to eliminate potentially flawed materials, mainly in strip thickness and surface quality.

Dimension Inspection

To test completely outside diameter, thickness and length to comply to the precise dimensional tolerance range.

Pressure Test

Mechanical Properties

TestingTensile, hardness, flaring, flange, reverse bend tests to ensure proper yield stress and tensile strength.

Eddy Current Testing

Uses electromagnetic induction to identify defects in the piping and guarantee the air tightness.

PMI

The analysis of a metallic sample to identify the material grade. This is accomplished by measuring the % composition of its constituent elements and matching it to a database of known alloys.

Quality and Testing

Our factory has striven to meet the highest standards demanded by customers, as well as by national and international standards. Our technicians work hard to evaluate and homologate manufacturers and mills, monitoring manufacturing and material testing. We verify testing and MTCs, guaranteeing each material supplied to the QUALITY of the products delivered. The tests include Destructive tests and non destructive tests.

Certified ISO 9001:2015 for Quality Management Systems.

Laboratory testing to meet requisite quality standards.

Experienced and trained quality inspectors.

Sourcing tested materials from reputed and well established manufacturer / suppliers.

Package Solution

Hex bundle outside with woven bag

Wooden box

Ends with plastic caps