We produce ASTM A312 TP 304 welded stainless steel pipe in different sizes and dimensions to meet project requirements, pipe sizes and dimensions in NPS range from 1/8 inch to 48 inch, wall thickness in Schedule range from SCH 5 to Sch 160.

ASTM A312 Gr TP304 and UNS S30400 Stainless Steel 304 Welded Pipe manufacturer in China, Annealed and Pickled, Polished, Bright Annealed, Cold Drawn finishes.

ASTM A312 TP 304 stainless steel is the most standard used alloy grade. Essentially, Grade 304 is an austenitic chromium alloy which is also known as an “18/8” stainless as the make-up of the steel is 18% chromium and 8% nickel. ASTM A312 TP304 alloy has excellent resistance against corrosive and oxidative media across stress-induced environments. ASTM A312 TP304 Welded Pipe can be processed via the hot or cold rolling process, sheets or strips are rolled and welded in various welding procedures, like TIG and ERW welding methods. ASTM A312 TP304 Welded Pipes are produced by welding the metal longitudinally to precisely shape the pipes. These pipes are very durable and don’t require any filler material to weld.

| Standard | ASTM A312, ASME SA312 |

|---|---|

| Stainless Steel | TP 304, SS 304 |

| Pipe Type | Welded Round Pipe |

| Finishes | Annealing Pickling, as welded, polished |

| Outside Diameter | 1/8 Inch To 42 Inch 10.3 – 1219 mm DN 6 – DN 1200 |

| Wall Thickness | Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160 |

| Dimensional Specifications | ANSI/ ASME B36.19M, ANSI/ ASME B36.10M |

| Pipe Ends | Plain end, Beveled end and Treaded End |

| Application | high-temperature and general corrosive service |

ASTM A312 TP 304 Stainless Steel

ASTM A312 TP 304 Stainless Steel is the most used 300 series stainless steel grade, it combines of sufficient Chrome and Nickel contents to possess excellent properties, ASTM A312 TP 304 has good corrosion resistance, good formability and good weldability to meet various applications.

ASTM A312 TP304 stainless steel chemical composition.

| Grade | C | Mn | P | S | Si | Ni | Cr | Fe |

|---|---|---|---|---|---|---|---|---|

| TP304 | 0.08 | 2.00 | 0.045 | 0.030 | 1.0 | 8-11 | 18-20 | Bal. |

ASTM A312 TP304 stainless steel mechanical properties:

| Tensile Strength(Mpa) Max | Yield Point(Mpa) Max | Elongation(%) | Hardness (HRB) Max | |

|---|---|---|---|---|

| TP304 | 515 | 205 | 35 | 92 |

ASTM A312 TP 304 Equivalent Grades

| GRADE | UNS | EN | JIS | WERKSTOFF NR. | GOST |

| USA | EUROPE | JAPAN | GERMAN | RUSSIAN | |

| ASTM A312 TP 304 | S30400 | X5CrNi18-10 | SUS 304 | 1.4301 | 08Х18Н10 |

Type 304L is a lower carbon variant of Grade 304 the steel can be welded without the resulting issue of carbon precipitation, sometime, 304/304L dual grade is required.

ASTM A312 TP304 Welded Stainless Steel Pipe Quality Control

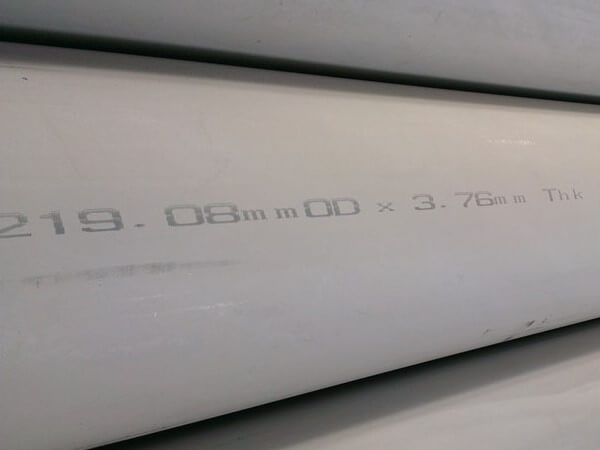

Tolerance: ASTM A312 specification specified outside diameter and wall thickness limitations, OD tolerance conform to ASTM A999.

Outside Diameter

| Outside Diameter, NPS | Tolerance, Inch |

|---|---|

| 1/8 To 1-1/2, Incl | Over 1/16 Under 1/32 |

| Over 1-1/2 To 4, Incl | Over 1/32 Under 1/32 |

| Over 4 To 8, Incl | Over 1/16 Under 1/32 |

| Over 8 To 18, Incl | Over 3/32 Under 1/32 |

| Over 18 To 26, Incl | Over 1/8 Under 1/32 |

| Over 26 To 34, Incl | Over 5/32 Under 1/32 |

| Over 34 To 48, Incl | Over 3/16 Under 1/32 |

Wall Thickness

| Outside Diameter | Wall Thickness Tolerance, % |

|---|---|

| 1/8 To 2-1/2 Incl., All T/D Ratios | Over 20.2 Under 12.5 |

| Over 3 To 18 Incl., T/D Up To 5% Incl. | Over 22.5 Under 12.5 |

| Over 3 To 18, Incl., T/D > 5% | Over 15.0 Under 12.5 |

| 20 And Large, Welded, All T/D Ratios | Over 17.5 Under 12.5 |

| 20 And Large, Seamless, T/D Up To 5% Incl. | Over 22.5 Under 12.5 |

| >20 And Large, Seamless, T/D > 5% | Over 15.0 Under 12.5 |

Standard Testing And Inspection

- Mechanical Tests

- Grain Size Determinations

- Weld Decay Tests

- Transverse or Longitudinal Tension Test

- Hydrostatic or Nondestructive Electric Test

- Flattening Test (option)

- Radiographic Examination (option)

- Intergranular Corrosion Test (option)

- Weld Decay Test (option)

Dimensions Of ASTM A312 TP304 Stainless Steel Pipe

| NPS | DN | OD, mm | SCH 5s | SCH l0s | SCH 10 | SCH 20 | SCH 30 | SCH 40s | SCH STD | SCH 40 | SCH 60 | SCH 80s | SCH XS | SCH 80 | SCH 100 | SCH 120 | SCH 140 | SCH 160 | SCH XXS |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/8 | 6 | 10.3 | 1.24 | 1.73 | 1.73 | 1.73 | 2.41 | 2.41 | 2.41 | ||||||||||

| 1/4 | 8 | 13.7 | 1.65 | 2.24 | 2.24 | 2.24 | 3.02 | 3.02 | 3.02 | ||||||||||

| 3/8 | 10 | 17.1 | 1.65 | 2.31 | 2,31 | 2.31 | 3.20 | 3.20 | 3.20 | ||||||||||

| 1/2 | 15 | 21.3 | 1.65 | 2.11 | 2.77 | 2.77 | 2.77 | 3.73 | 3.73 | 3.73 | 4.78 | 7.47 | |||||||

| 3/4 | 20 | 26.7 | 1.65 | 2.11 | 2.87 | 2.87 | 2.87 | 3.91 | 3.91 | 3.91 | 5.56 | 7.82 | |||||||

| 1 | 25 | 33.4 | 1.65 | 2.77 | 3.38 | 3.38 | 3.38 | 4.55 | 4.55 | 4.55 | 6.35 | 9.09 | |||||||

| 1 1/4 | 32 | 42.2 | 1.65 | 2.77 | 3.56 | 3.56 | 3,56 | 4.85 | 4.85 | 4.85 | 6.35 | 9.70 | |||||||

| 1 1/2 | 40 | 48.3 | 1.65 | 2.77 | 3.68 | 3.68 | 3.68 | 5.08 | 5.08 | 5.08 | 7.14 | 10.15 | |||||||

| 2 | 50 | 60.3 | 1.65 | 2.77 | 3.91 | 3.91 | 3.91 | 5.54 | 5.54 | 5.54 | 8.74 | 11.07 | |||||||

| 2 1/2 | 65 | 73 | 2.11 | 3.05 | 5.16 | 5.16 | 5.16 | 7.01 | 7.01 | 7.01 | 9.53 | 14.02 | |||||||

| 3 | 80 | 88.9 | 2.11 | 3.05 | 5.49 | 5.49 | 5.49 | 7.62 | 7.62 | 7.62 | 11.13 | 15.24 | |||||||

| 3 1/2 | 90 | 101.6 | 2.11 | 3.05 | 5.74 | 5.74 | 5.74 | 8.08 | 8.08 | 8.08 | |||||||||

| 4 | 100 | 114.3 | 2.11 | 3.05 | 6.02 | 6.02 | 6.02 | 8.56 | 8.56 | 8.56 | 11.13 | 13.49 | 17.12 | ||||||

| 5 | 125 | 141.3 | 2.77 | 3.40 | 6.55 | 6.55 | 6.55 | 9.53 | 9,53 | 9.53 | 12.70 | 15.88 | 19.05 | ||||||

| 6 | 150 | 168.3 | 2.77 | 3.40 | 7.11 | 7.11 | 7.11 | 10.97 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | ||||||

| 8 | 200 | 219.1 | 2.77 | 3.76 | 6.35 | 7.04 | 8.18 | 8.18 | 8.18 | 10.31 | 12.70 | 12.70 | 12.70 | 15.09 | 18.26 | 20.62 | 23.01 | 22.23 | |

| 10 | 250 | 273.1 | 3.40 | 4.19 | 6.35 | 7.80 | 9.27 | 9.27 | 9.27 | 12.70 | 12.70 | 12.70 | 15.09 | 18.26 | 21.44 | 25.40 | 28.58 | 25.40 | |

| 12 | 300 | 323.9 | 3.96 | 4.57 | 6.35 | 8.38 | 9.53 | 9.53 | 10.31 | 14.27 | 12.70 | 12.70 | 17.48 | 21.44 | 25.40 | 28.58 | 33.32 | 25.40 | |

| 14 | 350 | 355.6 | 3.96 | 4.78 | 6.35 | 7.92 | 9.53 | 9.53 | 11.13 | 15.09 | 12.70 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | |||

| 16 | 400 | 406.4 | 4.19 | 4.78 | 6.35 | 7.92 | 9.53 | 9.53 | 12.70 | i6.66 | 12.70 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | |||

| 18 | 450 | 457.2 | 4.19 | 4.78 | 6.35 | 7.92 | 11.13 | 9.53 | 14.27 | 19.05 | 12.70 | 23.83 | 29.36 | 34.93 | 39,67 | 45.24 | |||

| 20 | 500 | 508 | 4.78 | 5.54 | 6.35 | 9.53 | 12.70 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 | 32.54 | 38.10 | 44.45 | 50.01 | |||

| 22 | 559 | 4.78 | 5.54 | 6.35 | 9.53 | 12.70 | 9.53 | 22.23 | 12.70 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | |||||

| 24 | 600 | 610 | 5.54 | 6.35 | 6.35 | 9.53 | 14.27 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | |||

| 26 | 660 | 7.92 | 12.70 | 9.53 | 12.70 | ||||||||||||||

| 28 | 700 | 711 | 7.92 | 12.70 | 15.88 | 9.53 | 12.70 | ||||||||||||

| 30 | 762 | 6.35 | 7.92 | 7.92 | 12.70 | 15.88 | 9.53 | 12.70 | |||||||||||

| 32 | 800 | 813 | 7.92 | 12.70 | 15.88 | 9.53 | 17.48 | 12.70 | |||||||||||

| 34 | 884 | 7.92 | 12.70 | 15.88 | 9.53 | 17.48 | 12.70 | ||||||||||||

| 36 | 900 | 914 | 7.92 | 12.70 | 15.88 | 9.53 | 19.05 | 12.70 | |||||||||||

| 38 | 965 | 9.53 | 12.70 | ||||||||||||||||

| 40 | 1000 | 1016 | 9.53 | 12.70 | |||||||||||||||

| 42 | 1067 | 12.70 | 15.88 | 9.53 | 19.05 | 12.70 | |||||||||||||

| 44 | 1100 | 1118 | 9.53 | 12.70 | |||||||||||||||

| 46 | 1168 | 9.53 | 12.70 | ||||||||||||||||

| 48 | 1200 | 1219 | 9.53 | 12.70 | |||||||||||||||

| 52 | 1321 | ||||||||||||||||||

| 56 | 1422 | ||||||||||||||||||

| 60 | 1524 |

Welded Pipe Manufacturing

Four different welding processes are typically used for making tube. Since there is no filler metal in these welds, the welds are at least as strong as the parent metals.

High Frequency (HF) Welding. Today, most mild steel and aluminum tube is welded with HF welders, which are also suitable for 400 series stainless and even 300 series if the tubing is for decorative use.

Nearly 95 percent of the HF welders sold are solid-state, using transistors to generate the alternating frequency current. Research has been undertaken to weld products less than 1/4 inch in diameter and to extend the ability of the welder to produce a pressure-quality weld on 300 stainless steel at high line speeds.

Compared to other welding techniques, high frequency is somewhat forgiving of less-than-perfect edge registration.

Electric Resistance Welding (ERW). Low-frequency welding, accomplished through a rotating copper electrode, is used most often for mild steel tube from 0.250 to 0.375 inch in diameter.

This process is most suitable for the smallest diameters, as the impeders needed for HF welding cannot fit into the tiny tubes.

Electric resistant weld (ERW) is fabricated from coil. Significant hardness increase due to rapid cooling rate of the ERW seam can be encountered as a result of the fast fabrication process and possible malfunction of the induction heater.

Gas Tungsten Arc Welding (GTAW). GTAW is used for pressure-quality welds on 300 series stainless steel at slower welding speeds. It produces a good weld with little bead.

A welding torch with a tungsten tip, usually employing argon or an argon/oxygen mixture, heats the edges of the strip until the metal begins to melt or puddle, and the next pair of rolls squeezes the strip edges together. Here, edge registration is critical.

Laser Welding. The cost of laser welding is high relative to that of GTAW, although it is faster. It is used primarily for exotic metals and 300 series stainless steel, though some manufacturers use it on 400 series stainless.

Laser welding produces the smallest heat-affected zone (HAZ) and a bead even smaller than that produced by GTAW. Since there is almost no change in the grain structure of the parent metal, the finished piece has greater flexibility than a GTAW part. However, with this technique, edge registration is more critical than with the others.

304 Stainless Steel Pipe

- ASME SA312 TP304 SCH 10S Welded Pipes

- Sch80s A312 TP304 Stainless Steel SUS 304 Welded Pipes

- ASTM A312 Schedule 40S GR- TP304

- 1.4301 SS 304 Stainless Steel Pipes

- UNS S30400 Bright Annealed Pipes

- ASTM A312 304 SS Cold Drawn Seamless Pipes

- ASTM A312 304 SS Stainless Steel Pipe

- SS 304 Hollow Section

- Stainless Steel SUS 304 heavy wall Pipes

- SS 304 / 1.4301 large diameter stainless steel pipe

- ASME SA312 TP304 SS EFW Pipe

- UNS S30400 Industry Pipe